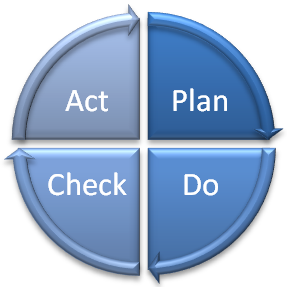

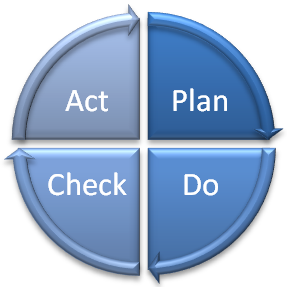

ISO 50001 is not just about non conformity prevention it sets targets for energy performance improvements and examines if they have been achieved. It also ensures continuous improvement through the use of the “Plan – Do – Check – Act” (PDCA) cycle.

ISO 50001 is not just about non conformity prevention it sets targets for energy performance improvements and examines if they have been achieved. It also ensures continuous improvement through the use of the “Plan – Do – Check – Act” (PDCA) cycle.

The PDCA cycle is the basis of every ISO standard and it consists of:

- Plan – Establish guidelines and provisions for a Energy Management System operation following ISO 50001

- Do – Operate the business under the new Energy Management System

- Check – Verify that you operate business under the established Energy Management System following ISO 50001

- Act – report the result of verification at management review

Plan

The overall Energy Management System is outlined in the first step and it provides guidelines for its implementation and control.

Management Role

When establishing a new EnMS top management commitment is crucial as they appoint and authorise projects for the EnMS champion. The EnMS champion is a chosen higher management representative that directs activities down to the team and effectively to the whole organisation. Top management’s other activities would include allocating resources, setting performance ownership, ensure fair evaluation, direct the management review and define the energy policy.

Energy Policy

A new energy policy has to be created in line with the ISO 50001 requirements. The energy policy must be coherent with the nature, the scale of, and the impact on the organisation’s energy use as it will effectively become a framework for setting and reviewing energy objectives and targets. The energy policy should emphasize commitment to continual improvement in energy performance and ensure availability of information and resources authorised by top management.

The top management must be sure that the energy policy is documented, communicated and understood within the organisation for a successful implementation of an Energy Management System, in line with ISO 50001. The Energy Management System should also be reviewed and updated when necessary

Do

This step involves energy planning, and implementation and operation.

Energy Review

An energy review has to be conducted firstly. The energy review analyses energy use based on measurements and other data, identifies areas of energy use and consumption and prioritises and records opportunities for improving energy performance. An example would be the usage of renewable sources, alternative energy sources and other energy conservation opportunities (ECOs). The energy review defines a baseline and target and is used as evidence of energy performance improvement. Energy performance indicators (EnPIs) are also identified and objectives, targets and energy management action plans created.

Implementation and Operation

The implementation and operation consists of applying six additional elements in establishing the energy management action plan:

- Competence, training and awareness – resources should be put in place that ensure that the Energy Management team has adequate skills to control the EnMS

- Communication – appropriate communication channels should be defined

- Documentation – a system for the requirements and control of procedures and plans has to be in place

- Operational control – general guideline and provision for overall EnMS operation

- Design – guideline to reduce energy by reviewing the designs of facilities and manufacturing processes

- Procurement of energy services, products and equipment – the collaboration with suppliers is key in becoming a ‘greener’ organisation

The ISO 50001 does not mention product design but it is part of ISO 14001; the reason for its exclusion is that product design does not necessarily deal with energy even though it could affect it

Check

This step involves checking of performance and it is done in four parts which are:

- Monitoring, measurement and analysis – as by designed guidelines and procedures

- Non conformities, correction, corrective and preventative actions – this ensures continual improvement of the energy management system

- Evaluation of compliance with legal and other requirements – the EnMS has to stay alert; the recorded information can be presented during management review to serve EnMS purpose

- Internal audit of the energy management system – can be conducted as a part of organisation’s audit programme. It examines that the EnMS conforms to energy objectives and target that have been established and that the EnMS is properly implemented and energy performance improved

At planned intervals a performance review must be done, the guidelines and procedures prepared in the previous steps should make this process easy to conduct. All documents and reports are then prepared for the management review

Act

One of the most important EnMS processes is the management review. Management review:

- Reassures top management role and responsibility

- Accelerates the EnMS progress for continual improvement

- Evaluate’s people’s effort

- Understands and recognises the changes made

It is the output of the management review not the analysis that drives the EnMS forward. If necessary the management review should conduct changes in energy performance or energy performance indicators, changes in energy policy, objectives, targets or baseline and should allocate resources appropriately

Benefits of Implementing an Energy Management System

Benefits of Implementing an Energy Management System

ISO 50001 is not just about non conformity prevention it sets targets for energy performance improvements and examines if they have been achieved. It also ensures continuous improvement through the use of the “Plan – Do – Check – Act” (PDCA) cycle.

ISO 50001 is not just about non conformity prevention it sets targets for energy performance improvements and examines if they have been achieved. It also ensures continuous improvement through the use of the “Plan – Do – Check – Act” (PDCA) cycle.